- Home

- Forums

- National and International Business System Standards

- Food and Drug (Pharmaceuticals) related Regulations

- US Food and Drug Administration (FDA)

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ICH Q10 vs. ISO 9001 vs. ISO 13485 and FDA 210-211 - Differences

- Thread starter v9991

- Start date

Re: ICH Q10 vs. ISO 9000 vs. ISO 13485 and FDA 210-211 - Differences

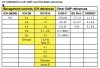

These may help as a 'starter'.

In the stuff I have read, they mix up ISO 9001 with ISO 9000 (such as in the chart attached) so be careful.

These may help as a 'starter'.

In the stuff I have read, they mix up ISO 9001 with ISO 9000 (such as in the chart attached) so be careful.

Attachments

Thanks Marc, that word of caution helps;

And, I certainly have long a way to go in this direction. (it includes, not only traveling in that direction, but also (if not inventing...)discovering it first! ; )

a quick note/context of my query;

1) what does it take to align CFR 210-211 based quality system to align with ICH Q10 (perception being that ICH Q10 being most current guidance ...is aligned with current concepts/definitions of Quality by Design)

2) or to check, if its worthwhile the effort to align/upgrade the systems.

3) Are there any literature/experiences available in this area?

added as clarification...(19-01-2011)

Its about systems of typical ANDA drug product manufacturing company.(I was probably assuming that, since the selected sub group is for CFR 210-211 so the scope scope would be obvious)

Further, It certainly makes sense to improve towards better-robust-current system.,

But how do we establish the same need through objective assessment " the need/advantages of moving towards either ICH Q10 or ISO 13485". (here assumption is that these documents are more concurrent and need is to convince the management with the advantages of moving towards that)

And, I certainly have long a way to go in this direction. (it includes, not only traveling in that direction, but also (if not inventing...)discovering it first! ; )

a quick note/context of my query;

1) what does it take to align CFR 210-211 based quality system to align with ICH Q10 (perception being that ICH Q10 being most current guidance ...is aligned with current concepts/definitions of Quality by Design)

2) or to check, if its worthwhile the effort to align/upgrade the systems.

3) Are there any literature/experiences available in this area?

added as clarification...(19-01-2011)

Its about systems of typical ANDA drug product manufacturing company.(I was probably assuming that, since the selected sub group is for CFR 210-211 so the scope scope would be obvious)

Further, It certainly makes sense to improve towards better-robust-current system.,

But how do we establish the same need through objective assessment " the need/advantages of moving towards either ICH Q10 or ISO 13485". (here assumption is that these documents are more concurrent and need is to convince the management with the advantages of moving towards that)

Last edited:

AnaMariaVR2

Trusted Information Resource

Dear v9991:

More information is needed in order to answer your questions. It all depends on your product, your market, customer satisfaction, what is your company's evolutionary journey within quality standards, the design space for your drug product, risks vs. benefits, the compliance issues related to your product, if financially this makes sense to the company or the product...& other factors as well. I could go on & on some more.

Bottom line is that if it makes sense to built quality into your product & you can meet those standards & deliver it, then that new path should be explored. The key is "if it makes sense". Does it?

More information is needed in order to answer your questions. It all depends on your product, your market, customer satisfaction, what is your company's evolutionary journey within quality standards, the design space for your drug product, risks vs. benefits, the compliance issues related to your product, if financially this makes sense to the company or the product...& other factors as well. I could go on & on some more.

Bottom line is that if it makes sense to built quality into your product & you can meet those standards & deliver it, then that new path should be explored. The key is "if it makes sense". Does it?

Thank you AnaMariaVR2, Your comments certainly provide directions for point no. 2) of my query;

I sense the 'generality' of description/approach in my query; and here is clarification, ... its about systems of typical ANDA drug product manufacturing company.(I was probably assuming that, since the selected sub group is for CFR 210-211 so the scope scope would be obvious)

that, since the selected sub group is for CFR 210-211 so the scope scope would be obvious)

Further, It certainly makes sense to improve towards better-robust-current system.,

But how do we establish the same need through objective assessment " the need/advantages of moving towards either ICH Q10 or ISO 13485". (here assumption is that these documents are more concurrent and need is to convince the management with the advantages of moving towards that)

I sense the 'generality' of description/approach in my query; and here is clarification, ... its about systems of typical ANDA drug product manufacturing company.(I was probably assuming

Further, It certainly makes sense to improve towards better-robust-current system.,

But how do we establish the same need through objective assessment " the need/advantages of moving towards either ICH Q10 or ISO 13485". (here assumption is that these documents are more concurrent and need is to convince the management with the advantages of moving towards that)

AnaMariaVR2

Trusted Information Resource

I will look into what are the industry standards for your product, time & resources available, what are your competitors doing & your own quality goals.

Make a gap analysis to see where you are & feasibility study to see if it is worth it, if you'll gain anything, if it makes sense. Objectively, the numbers will support the argument after your assessment. But don't massage the numbers just to move into ICH Q10 vs. ISO 9001 vs. ISO 13485, that is not the point.

A compare/contrast study should be included to show the strengths & limitations of your current quality system against the estimate that you will present if your company hypothetically would moved towards ISO 9001 or ICH Q10 or ISO 13485 (Med.Dev. QMS). You will also have to educate management about these other standards and what value they will add in reality or not to the company & your product. Depends on the time frame & support you will have at hand at the end. Committees can choose on 1 standard to follow & implement, but your company might decide to create its own hybrid quality system (captured in Quality Manual, policies, SOPs, etc.) that can be a fusion of the best of each of those standards that you mentioned...again...if it makes sense & is relevant to your product!

Good luck

Make a gap analysis to see where you are & feasibility study to see if it is worth it, if you'll gain anything, if it makes sense. Objectively, the numbers will support the argument after your assessment. But don't massage the numbers just to move into ICH Q10 vs. ISO 9001 vs. ISO 13485, that is not the point.

A compare/contrast study should be included to show the strengths & limitations of your current quality system against the estimate that you will present if your company hypothetically would moved towards ISO 9001 or ICH Q10 or ISO 13485 (Med.Dev. QMS). You will also have to educate management about these other standards and what value they will add in reality or not to the company & your product. Depends on the time frame & support you will have at hand at the end. Committees can choose on 1 standard to follow & implement, but your company might decide to create its own hybrid quality system (captured in Quality Manual, policies, SOPs, etc.) that can be a fusion of the best of each of those standards that you mentioned...again...if it makes sense & is relevant to your product!

Good luck

Last edited:

What is the advantage of an FDA compliance facility/systems for going towards ICH Q10 OR ICH 9000.

what difference between Q10 vs ISO 9000/13485 and FDA CFR 210-211.

Answer 1

If you refer the Federal Register (attached), it says the following -

The draft guidance applies to drug substances and drug products, including

biotechnology and biological products, throughout the product lifecycle. The

draft guidance is intended to provide a comprehensive approach to an effective pharmaceutical quality system that is based on International Organization for Standardization (ISO) concepts, includes applicable good manufacturing practice (GMP) regulations, and complements the ICH guidances on ‘‘Q8 Pharmaceutical Development’’ and ‘‘Q9 Quality Risk Management.’’

Answer 2

Since this is based on ISO concept, the framewoek is same but focuses on Pharmaceutical Quality System requirements in particular. The Q10 approach makes the classical 21 CFR parts 210 and 211 more "cuurent" and thus like cGMP

.

Attachments

May be the experts have already indicated the answers, but I am unable to pick the cue from it . Pl. help me out.

. Pl. help me out.

For a FDA audited/approved facility; the question to beat is, why do we need to get into defining various levels of documents; viz., Quality Policy, Quality Plan etc., especially when these documents are not verified by FDA-Auditors + facility has been approved long without direct influence of them.

(this might be because, ....typically what drives the effectiveness of the quality sysems in pharma facility is about adequacy& compliance of systems/documentation and processes to ensure compliance...ie., "ensuring completeness and correctness of the process/outcome"); of course now a days the emphasis is slowly moving towards CAPA(improvements) and process controls.

I haven't worked directly with ISO systems., but they seem to need certain over-arching documents over and above the CFR 210-211 requirements.

viz., Quality policy(management commitment & Direction), Quality Plan/Manual(measurable objectives) which necessarily seem to provide overview of rest of the processes/SOP implemented.

at a conceptual level, i can interpret that Quality Policy/Plan provide certain amount of direction/commitment of management; BUT how to answer/convince the value addition of adopting Q10/ISO processes

thanks in advance for your thoughts.

For a FDA audited/approved facility; the question to beat is, why do we need to get into defining various levels of documents; viz., Quality Policy, Quality Plan etc., especially when these documents are not verified by FDA-Auditors + facility has been approved long without direct influence of them.

(this might be because, ....typically what drives the effectiveness of the quality sysems in pharma facility is about adequacy& compliance of systems/documentation and processes to ensure compliance...ie., "ensuring completeness and correctness of the process/outcome"); of course now a days the emphasis is slowly moving towards CAPA(improvements) and process controls.

I haven't worked directly with ISO systems., but they seem to need certain over-arching documents over and above the CFR 210-211 requirements.

viz., Quality policy(management commitment & Direction), Quality Plan/Manual(measurable objectives) which necessarily seem to provide overview of rest of the processes/SOP implemented.

at a conceptual level, i can interpret that Quality Policy/Plan provide certain amount of direction/commitment of management; BUT how to answer/convince the value addition of adopting Q10/ISO processes

thanks in advance for your thoughts.

May be the experts have already indicated the answers, but I am unable to pick the cue from it. Pl. help me out.

For a FDA audited/approved facility; the question to beat is, why do we need to get into defining various levels of documents; viz., Quality Policy, Quality Plan etc., especially when these documents are not verified by FDA-Auditors + facility has been approved long without direct influence of them.

(this might be because, ....typically what drives the effectiveness of the quality sysems in pharma facility is about adequacy& compliance of systems/documentation and processes to ensure compliance...ie., "ensuring completeness and correctness of the process/outcome"); of course now a days the emphasis is slowly moving towards CAPA(improvements) and process controls.

I haven't worked directly with ISO systems., but they seem to need certain over-arching documents over and above the CFR 210-211 requirements.

viz., Quality policy(management commitment & Direction), Quality Plan/Manual(measurable objectives) which necessarily seem to provide overview of rest of the processes/SOP implemented.

at a conceptual level, i can interpret that Quality Policy/Plan provide certain amount of direction/commitment of management; BUT how to answer/convince the value addition of adopting Q10/ISO processes

thanks in advance for your thoughts.

Probably you missed the meaning of my earlier post.

21 CFR parts 210 and 211 are like the GMPs. FDA focuses on cGMP (the small c that means current) which has lot of guidance and standards under its fold and you are expected to stay current with the FDA expectations.

If you hear about Process Analytical Technology (PAT), 21 CFR Part 11, Risk Based approach, Quality by Design (QbD), they are not in 21 CFR Parts 210 and 211 but a result of the cGMP (small c for current)

I would suggest that you go through this message from Janet Woodcock, who is the head of "Council for Pharmaceutical Quality" and this would address all your concerns.

Btw, FDA Inspector may not look into all the aspects what is expected during FDA inspection, but as a manufacturer, its our responsibility to comply with the FDA expectations.

Hope that is clear - pl come back if you have further questions

Similar threads

- Replies

- 4

- Views

- 729

- Replies

- 1

- Views

- 134

- Replies

- 3

- Views

- 110

- Replies

- 11

- Views

- 746