B

Bjourne

Hello,

Seems to be a very intellectual group of guys here

I'm new here to this forum(I usually just visit and participate in security forums such as Wilderssecurity and MalwareTips) and I just wanted to know more about Capability study. I am not an engineering graduate but have been exposed to semiconductor manufacturing process way back 2007 as I work in molding department for IC encapsulation. I want to learn more about the process side of things in our company but sad to say there isn't any training available or if there is I am darn busy at the production line(most of the time).

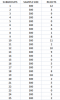

I have some notes that I got from some of our engineers. Some notes that they use for Capability studies but I am having a hard time learning it. Can I post it here so someone might check if I did it wrong...?

This is a sort of self-studying just in case I get the slot for promotion or can transfer to another company...just wanna learn more and not be stuck being a technician. I hope you understand.

Thanks for understanding.

Regards,

Bjourne

Seems to be a very intellectual group of guys here

I'm new here to this forum(I usually just visit and participate in security forums such as Wilderssecurity and MalwareTips) and I just wanted to know more about Capability study. I am not an engineering graduate but have been exposed to semiconductor manufacturing process way back 2007 as I work in molding department for IC encapsulation. I want to learn more about the process side of things in our company but sad to say there isn't any training available or if there is I am darn busy at the production line(most of the time).

I have some notes that I got from some of our engineers. Some notes that they use for Capability studies but I am having a hard time learning it. Can I post it here so someone might check if I did it wrong...?

This is a sort of self-studying just in case I get the slot for promotion or can transfer to another company...just wanna learn more and not be stuck being a technician. I hope you understand.

Thanks for understanding.

Regards,

Bjourne