Firstly, I apologize for my poor English.

Hi, could anyone tell us how to establish validation procedure for regulations and standards.

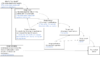

If there were user needs that the device is lightweight, we would write that the device must be X lbs +/- Y lbs and within Z inches in height as design input. Then, I would identify them on drawings or specifications as design verification. Finally, the resulting product would be tested in the actual or simulated use environment as a part of validation. It’s easy for us to understand this process but when it comes to “Regulations and Standards, we’ve been confused.

So far, that my opinion:

1.We would write that the device must comply with XYZ Regulations and Standards as design input. Design output is specifications.

2As Early stage of design verification, we would just identify that specifications state that the device must comply with XYZ Regulations and Standards (example: Must evaluate biocompatibility complying with ISO 109930-1).

3.End stage of design output would be biocompatibility test results.

4.AS end of design verification, we would just identify that biocompatibility test result.

5. We don't know how the resulting product validation

I know my recognition is wrong so, could anyone tell us correct procedure for design the verification/validation.

Hi, could anyone tell us how to establish validation procedure for regulations and standards.

If there were user needs that the device is lightweight, we would write that the device must be X lbs +/- Y lbs and within Z inches in height as design input. Then, I would identify them on drawings or specifications as design verification. Finally, the resulting product would be tested in the actual or simulated use environment as a part of validation. It’s easy for us to understand this process but when it comes to “Regulations and Standards, we’ve been confused.

So far, that my opinion:

1.We would write that the device must comply with XYZ Regulations and Standards as design input. Design output is specifications.

2As Early stage of design verification, we would just identify that specifications state that the device must comply with XYZ Regulations and Standards (example: Must evaluate biocompatibility complying with ISO 109930-1).

3.End stage of design output would be biocompatibility test results.

4.AS end of design verification, we would just identify that biocompatibility test result.

5. We don't know how the resulting product validation

I know my recognition is wrong so, could anyone tell us correct procedure for design the verification/validation.