If you define the earth conductor as PE, you end up with class I equipment. No way out. Definiton of class I: Protection against electrical shock depends on the protective earth and maybe insulation. Class II: Protection against electrical shock depends on reinforced or double insulation only.

The insulation concept assures that:

- short term / transient overvoltage do not result in an electrical shock

AND

- long term exposition / standard use does not result in an electrical shock.

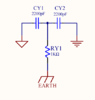

To achieve both, you have to implement the required clearances, creepages and dielectric strengths (MOOP, MOPP) and you have to pass the relevant leakage current test. But you cannot say, that creepage, clearance and dielectric strength is only important for transient overvoltages. This will certainly help you, to be below the leakage current limits. I have seen a lot of devices, having the required creepages, clearances and dielectric strengths, but still failing the leakage currents tests (for example due to Y-caps not selected properly).

Your device is not an actual ME equipment. But if you want to market it to be combined with ME equipment, you should pass the relevant requirements of 60601-1 / -1-11. Patient leakage current is not really aplicable here, but I have seen other manufacturers of power supplys, who make the patient leakage current test between secondary out and mains in. And if you are going to sell it to ME equipment manufacturers who want to comply with -1-11, you should try to pass patient leakage current tests without the earth. FE interruption is considered normal condition during leakage current testing.

And yes you are right, in "normal" hospital / professional setting PE interruption is single fault condition.

Regarding essential performance: I don't think that a power supply like yours has EP. It does not have a clinical function, were the degradation or loss of that functions leads to an unacceptable risk. Take care to not confuse essential performance with basic safety!

EP: Your device does not do something, that it actually should do (ventilate the patient, give an accurate reading, give an alarm)!

BS: Your c´device does something, that it actually should not do (shick you, start to burn, crush a finger).

Regarding EMC testing: As I have written in my first post, you should apply your risk management process here. 60601-1-2:2014 explicitely requires you to do this! You have to evaluate, if there are EMC related problems, that could lead to an unacceptable risk. But to be honest, I am not sure, if SFC condition have to be tested during EMC and if FE interruption is an "official" normal condition to be tested?!? Maybe an EMC expert could help here!?!