C

COGWMNF

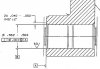

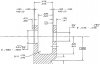

I need to design a receiving gage to accept a product with a primary hole and two concentric holes. My question is can I use a simple plate (location for datum A), a large pin (for datum B) and a stepped pin (for the concentric holes). What I am confused about in the perpendicularity requirement for the large hole (datum B). Does this requirement influence the gage pin size for the hole? In our company we usually make gage pins .0002 smaller than required for ease of fit. Therefore I'm planning on making the larger pin to a size of .5618 and the stepped pin to .4661 / .3103. Please review this and let me know if I'm on the right track. Thanks